Traditionally, pipe-bending is often considered an inevitably trial-and-error process. The misshapen bends and rough bits used to be expected, although these made the work more time-consuming and costly.

Nowadays, there are more advanced technologies for bending tubes and pipes with better quality and reliable output. You can now have your pipes customized to perfectly fit your designed electrical layout. The catch is knowing which service provider has the capacity to give you precise sizing, curves, and measurements. Knowing the basics of pipe bending can help you find the best team for the job.

Critical Factors for Pipe-Bending

It’s important to note which factors have the biggest impact on the final output of your project. For pipe-bending, these include the material of your pipe, the machine used, and your tooling methods.

Material

The process begins with knowing what kind of pipe you’ll be working on. Pipes with different nominal sizes also have varying wall thickness and tolerance. The wall thickness, outside diameter, and centerline radius are important to consider especially when making tight bends or using precision machines.

Machine

Pipe bending can be done using manual, motorized, or hydraulic machines. A conventional pipe bender is manually operated. Manual benders use mechanical force instead of electricity, so they are less costly. However, they are time-consuming and prone to errors.

Motorized benders take less time and are less strenuous than manual bending, but the angles and depths are still manually controlled, so there is still some chances of error.

Hydraulic pipe bending machines are more massive and require electricity. But they produce repeatable results of precisely measured bends.

Tooling

How you set up and use your tools and machines in your workspace also affect the outcome of your pipe bending job.

This means that certain builds of the tools should be preferred for certain types of materials. For instance, when your pipe is soft, you will get better results with a hard mandrel and vice versa. In other words, your skills in operating the machines to give you the curves that you want are as important as the type of machine you use.

Commonly-Used Pipe-Bending Methods

Roll Bending

Roll bending is often used for large pieces of pipes. Two or more massive rollers are positioned over and beneath the pipes and then moved mechanically or electrically to guide the pipes to the right bend. This is the preferred method for creating spiraled pipes.

Compression Bending

Similar to roll bending, this method uses a roller called compression die to bend the pipe around a stationary or fixed die. The compression is ideal for jobs that require identical bends since both ends can be compressed to the right curve with one compression set-up.

Ram-Type Roll Bending

This method uses hydraulic force to ram a portion of the pipe against pivot blocks or rollers. This generally provides you with the curve that you want although it is less controllable than other methods and also results in some wrinkling in the underside.

Rotary Draw Bending

For precision works and tight radius bend requirements, professionals often turn to rotary draw bending. The complex process simultaneously uses a mandrel, pressure dies, wiper dies, hydraulics and electronic servomotors to create accurate bends.

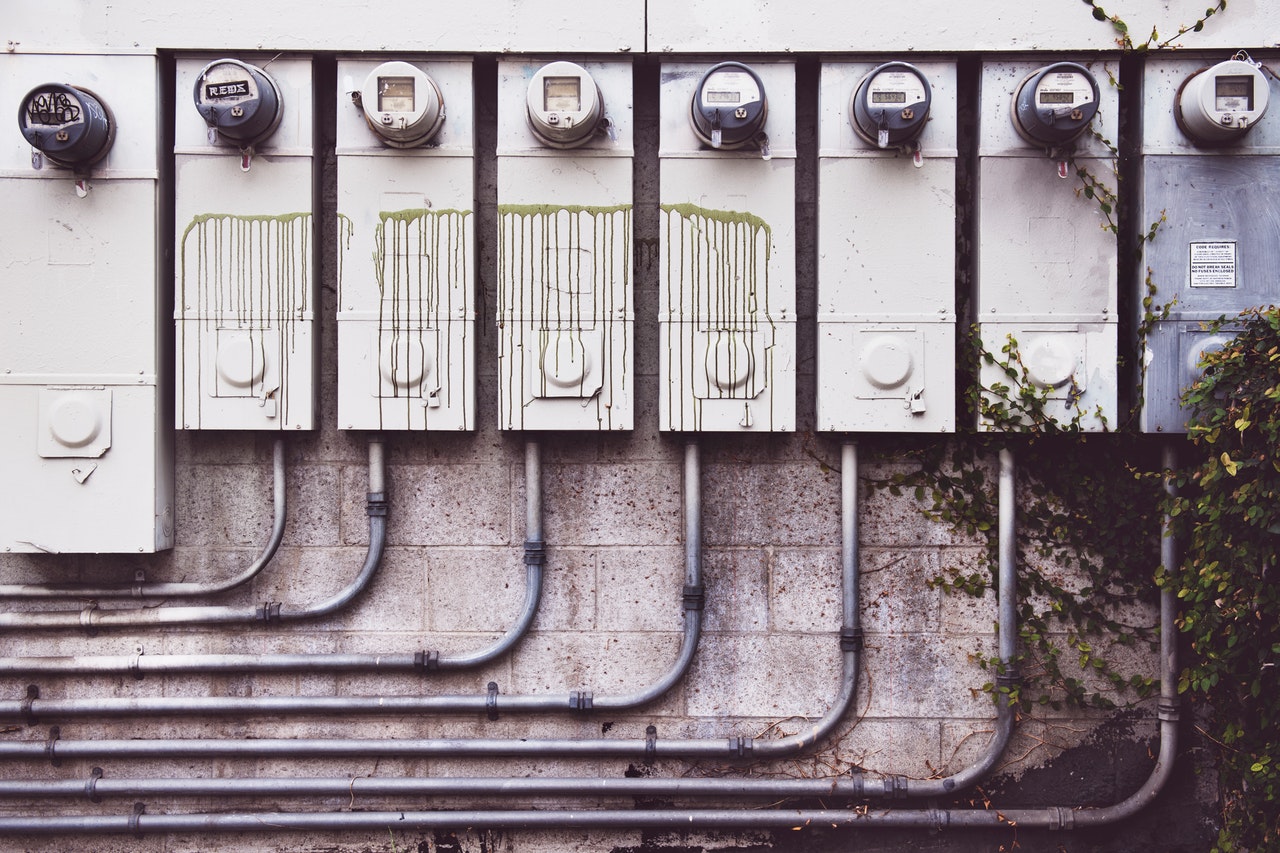

Let Professionals Handle The Task

If you run an electrical service company, pipe-bending may just be a secondary task but you understand the necessity to get this job right for safe and proper installation of electrical systems. Specialized facilities like USESI’s prefabrication workshop are always innovating for new technologies to increase efficiency and bring down related costs for custom bending your pipes. If you want to keep growing, leverage on this expertise to spur your overall efficiency and output quality.