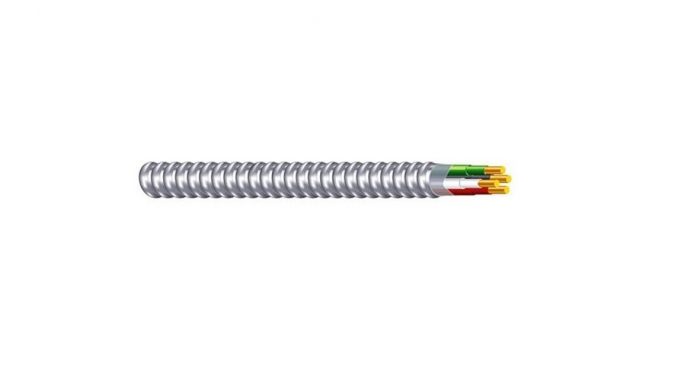

A Metal Clad Cable, also referred to as MC Cable, is a corrosion-resistant metal cable containing insulated copper or aluminum connectors.

Based on the National Electric Code’s (NEC) technical definition, it is “a factory assembly of one or more insulated circuits enclosed in an armor of interlocking metal tape, or smooth or corrugated metallic sheath.” Standard ones usually contain three connectors made of copper or aluminum.

COMMON USES FOR METAL CLAD CABLES

These cables can be found everywhere, and are mostly used for the following purposes:

- Service

- Feeders

- Branch Circuitry

- Subpanel to Main Electrical Panel

- Service Head to Main Electrical Panel

- Main Electrical Panel to Lighting Circuits

- Main Electrical Panel to Individual Outlets

ADVANTAGES OF USING METAL CLAD CABLES

MC Cables are used for most types of building construction, including residential, commercial, and industrial structures. Its popularity is mostly due to its versatile and economical use:

1. Serviceable in less-than-ideal conditions

The Metal Clad Cable includes a grounding wire and can be used in outdoor applications. It can go into concealed and unconcealed spaces, and even buried underground. The National Electric Code (NEC), it is also approves it for difficult locations that involve exposure to moisture and hazardous elements.

2. Economical alternative

MC Cables are relatively cheaper compared to pipe and wire installations. This is one main reason many builders use metal lad lines for their electrical installations. The absence of pull-boxes and conduits means installations come with less material costs and labor outlay.

3. Suitable for most builds

These Cables continue to grow in popularity because they can carry conductors as large as 2000 kcmil. Unlike armored cables and other limited options, Metal Clad Cables are fit for any type of electrical needs, from home use to warehouses, hotels, offices, and even stadiums and industrial plants.

4. Easy installation

Compared to other alternatives such as pipes, Metal Clad Cables are much faster to install. This eliminates the tedious conduit pre-installation before wire pulling, which saves a lot of time and manpower.

Interlocked MC Cables are also highly versatile. They are easy to cut and have no limits to the number of bends as long as they follow the bending diameter requirements. As a result, they are easier to work with during installations within large or complex electrical systems.

TIPS FOR WORKING WITH METAL CLAD CABLES

1. Use only metal junction boxes since plastic or fiberglass boxes could not hold Metal Clad Cables well.

2. Anti-short Bushings are cheap ways to add a layer of protection against accidental cuts to the conductors where the cable joins the connector.

3. The bending requirement for interlocked MC Cable is “seven times the external diameter of the metallic sheath.”

4. Whips, or short metal clad conduits with preinstalled connectors, are convenient options for connecting your appliances to the grid without cutting through your Metal Clad Cables.

THE BOTTOM LINE

The Metal Clad Cable is an affordable and flexible option for a wide variety of electrical uses. Its suitability with most types of structures and the easy installation makes it a smart choice for builders looking for efficiency and financial sense.